Guide to choosing pumps for dust suppression systems

Technical analysis of the characteristics required for a pump in an effective and durable dust suppression system

In many industrial environments, the presence of dust and particulate matter suspended in the air is a serious and multifactorial problem. In addition to compromising worker health and creating explosion risks in specific environments, dust can damage equipment and negatively affect product quality.

To solve this problem, dust suppression systems have become a standard solution, mainly thanks to their key component: the high-pressure pump. Obviously, choosing the right pump cannot be done at random and must be based on a thorough understanding of how these systems work and what characteristics are essential to achieve effectiveness, reliability, and safety. An unsuitable pump can render a dust suppression system inefficient, wasting water and energy without achieving the desired result. Conversely, a correctly chosen pump ensures the creation of a very fine mist (fog), which binds effectively to the dust, bringing it down to the ground.

Our guide aims to explore the essential features that the best pumps for dust suppression systems must have, providing a clear picture for an informed and targeted choice.

The principle of dust abatement systems

Spray dust suppression systems, also known as “fog” systems, operate according to a simple but extremely effective physical principle: agglomeration. Through a series of special nozzles, water is atomized into a mist composed of billions of micro-droplets, ranging in size from 1 to 50 microns. The size of these droplets is essential: they must be small enough not to wet surfaces and people but, at the same time, large enough to bind to dust particles suspended in the air.

When a micro-drop of water comes into contact with a dust particle, surface attraction causes them to join together in an agglomerate, and this new combined “weight” becomes heavy enough to cause the particle to fall to the ground, where it can be collected or washed away. To achieve this very fine mist, high pressures are required, which can vary depending on the nozzle used and the specific application. This is where the pump plays a fundamental role, as it is the only component in the system capable of providing the energy needed to transform the water into an efficient mist.

Essential features of dust suppression pumps

To function effectively in a dust abatement system, a pump must have a series of well-defined technical characteristics:

- High operating pressure: this is the determining factor for droplet size. To obtain a fine mist (fog) with droplets of the ideal size for agglomeration, it is necessary to operate at high pressure, typically between 50 and 80 bar. The pumps must be able to sustain and constantly supply this pressure throughout the entire work cycle;

- Adequate flow rate: this must be commensurate with the number and type of nozzles installed and the area to be covered. A high flow rate, combined with high pressure, allows large areas to be covered effectively or large volumes of dust to be treated.

- Durability and low maintenance: Dust suppression systems are often installed in hard-to-reach locations and are designed to operate continuously. It is essential that the pump is extremely reliable and requires low maintenance, minimizing downtime and operating costs.

Why piston technology is the ideal choice for dust suppression pumps

Piston technology proves to be the most effective solution for dust suppression pumps because it responds excellently to all the characteristics listed above. Piston pumps, by their very nature, are the only volumetric pumps capable of efficiently generating and sustaining the high pressures required for water atomization and guarantee:

- High pressure efficiency: unlike other pumps, piston technology maintains high volumetric efficiency even at very high pressures, which translates into lower energy consumption to produce the desired jet;

- Durability and reliability: the robust construction of piston pumps, often with ceramic pistons and nickel-plated brass or stainless steel heads, offers superior resistance to wear and corrosion, ensuring a long operating life even in harsh environments;

- Versatility: piston pumps are available in a wide range of flow rates and pressures, making them extremely versatile and adaptable to different system sizes, from smaller, localized systems to those that need to cover large industrial areas.

For these reasons, high-pressure piston pumps are the technology of choice for professional fogging systems, ensuring effective fog creation and long system life.

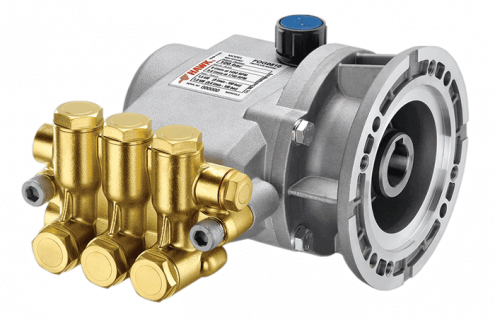

Hawk pumps for dust suppression systems

Hawk Pumps, specializing in high-pressure piston pumps, offers a range of specific products that are perfectly suited to the requirements of dust suppression systems. Our solutions are designed to guarantee the reliability, durability, and performance necessary for flawless operation. Among the various options available, the FOG Series stands out, with pumps that can operate at pressures of up to 100 bar and a maximum water temperature of 65°C. Their compact design makes them ideal for installation on small misting systems with limited flow rates. They are also perfect for small washing systems, such as those used for motorcycles.

Next is the XXT Series, consisting of pumps designed to guarantee high performance in professional applications. These models can operate at pressures of up to 200 bar, with a maximum flow rate of 70 l/min and a water temperature of up to 65°C.

Finally, the MXT Series is the optimal choice for the most demanding applications. With a maximum pressure of 200 bar and a flow rate of up to 100 l/min, these pumps are ideal for systems that require high water flow rates.

Choosing a Hawk pump means relying on a partner who understands your needs and offers you a solid, long-lasting technical solution. Contact us for personalized advice and to find the perfect pump for your system!

Share this Article