Calculating the power consumption of a pump

Understanding the formulas for calculating the power consumption of a pump in order to correctly size the motor and maximize efficiency

Those who work in the field of fluid systems cannot leave the choice and configuration of components to chance. To ensure that a pump operates efficiently and safely, it is essential to know the power required to drive it. This value, known as power consumption, is the starting point for selecting the most suitable motor (electric, combustion, hydraulic) for the task. Ignoring the calculation of power consumption can lead to a number of problems, such as motor overheating, overload, or under-performance, resulting in energy waste and premature failure.

Power consumption should not be confused with hydraulic power, which is the power actually transmitted to the fluid. Power consumption is always higher due to internal mechanical losses in the pump and represents the total power that the motor must supply to the pump shaft to operate it under certain pressure and flow conditions. Knowing how to calculate it correctly is an operation that combines theory and practice to achieve a balanced and efficient system.

What is the power consumption of a pump?

Power consumption is the total power required to operate a pump under certain working conditions. As mentioned, it differs from hydraulic power, which is the power required to move a certain volume of fluid at a given pressure. The relationship between the two is defined by the mechanical efficiency of the pump.

Hydraulic power (or fluid power) depends directly on two key parameters:

- Pressure (Prequest): the resistance encountered by the fluid and which the pump must overcome;

- Flow rate (Qrequest): the quantity of fluid displaced per unit of time.

To convert these values into a unit of power (such as horsepower - HP, or kilowatts - kW), specific constants are used that take into account the units of measurement employed. The following formulas represent a simplified calculation basis, widely used in practice for a quick estimate of the power required.

Calculating pump power consumption: the HP and kW formulas

To calculate the power absorbed by the pump, empirical formulas can be used that relate pressure and flow rate with a conversion coefficient. It is essential to pay attention to the units of measurement used in order to avoid incorrect calculations.

Here are the two main formulas for the calculation, used depending on whether you want to obtain the power in Horsepower (HP) or Kilowatts (kW):

Formula for Horsepower (HP):

HP = (Prequest * Qrequest) / 390

In this formula, the parameters must be expressed in imperial units:

- Prequest is the pressure required in PSI (Pound-force per Square Inch).

- Qrequested is the flow rate required in GPM (Gallons Per Minute).

- The coefficient 390 is an approximate value that takes into account the conversion factors between units and the average efficiency of a piston pump.

Formula for kilowatts (kW):

KW = (Prequest * Qrequest) / 520

In this formula, the parameters must be expressed in metric units:

- Prequested is the pressure required in BAR (Bar).

- Qrequested is the flow rate required in l/min (liters per minute).

- The coefficient 520 is an approximate value that takes into account conversion factors and the average efficiency of the pump.

The importance of calculating power consumption when selecting components

Accurate calculation of power consumption is not just a theoretical exercise, but an essential step in the design of a high-pressure system. Based on this value, fundamental decisions are made that will affect the efficiency, safety, and durability of the entire system.

The first component to be affected is obviously the motor: if undersized, it will not be able to provide the necessary power, leading to overheating, machine downtime, and ultimately failure; if oversized, on the other hand, it will result in unnecessarily high initial costs and, often, lower operating efficiency at partial loads. Calculating the power consumption allows you to find the right balance.

But the importance does not stop at the motor. The value of the power consumption influences the choice of electrical components such as power cables and protection devices, which must be sized to support the expected electrical load. Furthermore, knowing the power allows you to estimate the energy costs of operating the system, an increasingly important factor in terms of cost optimization and sustainability.

Furthermore, calculating the power consumption allows the pump's operating parameters to be correlated with the technical specifications provided by the manufacturer, ensuring that the pump is used within its optimal operating range to achieve maximum performance and longevity.

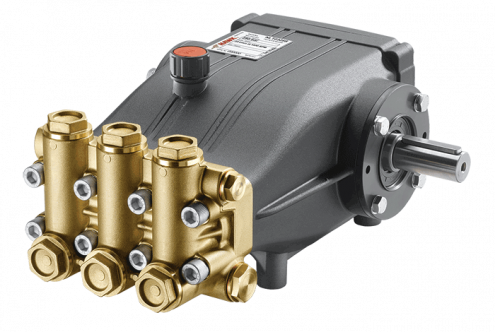

Hawk Pumps and the importance of calculation for your systems

Hawk Pumps, with its long experience in the manufacture of high-pressure piston pumps, knows how important it is to correctly calculate the power absorbed by a pump for the success of a project. For this reason, we supply piston pumps that represent the standard of excellence in terms of quality and reliability; however, their potential is only fully realized when they are incorporated into a well-designed system.

Consequently, in addition to providing products made from high-quality, durable materials, we offer our expertise to guide you in choosing the best solution.

For more information about our pumps and to receive technical support for your specific application, please contact us: our team of experts is at your complete disposal to provide you with the necessary advice, helping you make the best choice to achieve maximum efficiency and extreme durability for your system.

Share this Article