Maintenance of pressure relief valves: Hawk answers

Practical tips for preserving the efficiency and durability of pressure relief valves in high-pressure systems

Pressure relief valves are essential components in many industrial and professional systems that operate with high-pressure fluids. Their main function is to protect the entire system from dangerous overpressure by releasing excess fluid in a controlled manner, making them essential for operational safety and for protecting other components, such as pumps and pipes.

However, precisely because of the role they play and the often harsh conditions in which they operate, maintenance of pressure relief valves is not only recommended but absolutely essential to ensure their reliability and prolong their service life.

An improperly maintained pressure relief valve can cause significant problems, ranging from loss of system efficiency to catastrophic failure. Dust, debris, corrosion, and mechanical wear can compromise the operation of these safety devices, rendering them ineffective when needed. For this reason, understanding proper maintenance procedures is essential for every operator and plant manager.

Why maintenance of pressure relief valves is essential

The care and attention devoted to the maintenance of pressure relief valves are investments that pay off handsomely in terms of safety and efficiency; it is not just a matter of extending the life of the component, but of ensuring that the entire high-pressure system functions optimally and without risk.

Here are the main reasons why regular maintenance is essential:

- Extended system life: A malfunctioning pressure relief valve can put excessive stress on other system components, such as seals, fittings, and the pump. This constant stress accelerates wear and tear, reducing the overall operating life of the system. Keeping the valve in perfect condition also helps to preserve the integrity and functionality of all connected elements.

- Maintaining optimal performance: A valve that leaks pressure or does not close completely can cause a reduction in system efficiency, resulting in energy waste and lower operational performance. Regular maintenance prevents these leaks, ensuring that the desired operating pressure is maintained and that the system operates at peak capacity.

- Reduction in operating costs: prevention is always better than cure. Preventive maintenance of pressure relief valves is significantly less expensive than replacing damaged components or repairing sudden breakdowns: it avoids unexpected downtime, labor costs for emergency repairs, and the need to purchase spare parts at higher prices.

Procedures for proper maintenance of pressure relief valves

Proper maintenance of pressure relief valves should follow a well-defined schedule, tailored to the intensity of use and the type of fluids handled. Procedures may vary slightly depending on the specific valve model, but the general principles remain the same. Here are the main operations:

Regular visual inspection:

- frequency: this should be done before or after each work shift, or at least weekly, depending on use;

- what to check: the absence of obvious leaks from the fittings or valve body, the presence of corrosion, cracks, deformations, or any other signs of physical damage, and that the valve has no external residues or encrustations.

Functionality check:

- frequency: monthly or quarterly, depending on intensity of use;

- how to proceed: if possible, test the valve opening by bringing the system to a pressure high enough to activate it, listen for any abnormal noises during operation, and check that the valve closes completely once the pressure returns to normal levels.

Internal and external cleaning:

- Frequency: every 3-6 months

- What to clean: disassemble the valve and thoroughly clean all internal and external parts, removing any limescale deposits, rust, debris, or fluid residues that could hinder the movement of internal components. Use detergents that are compatible with the valve materials and the fluid being conveyed.

Checking, lubricating, and replacing seals:

- Frequency: during each cleaning operation;

- Importance: seals are essential for valve tightness, so they must be carefully inspected for signs of wear, cracking, hardening, or deformation and always replaced with original or equivalent spare parts, even if they do not appear visibly damaged, especially if the valve operates at high pressures or with aggressive fluids. Lubricate the seals each time they are checked or replaced. Also check that there is no encrustation or dirt on the valve seat and shutter. Lubricate the seals each time they are checked or replaced. Also check that there is no scale or dirt on the valve seat and shutter.

Calibration (if applicable):

- frequency: according to specific industry regulations;

- Importance: Some pressure relief valves, especially safety valves, require periodic calibration to ensure that they open at the preset pressure. This operation must be performed by qualified personnel using certified equipment.

In addition, it is advisable to keep a detailed record of all maintenance operations performed, including dates, types of intervention, parts replaced, and operator name; this helps to track the valve's history and schedule future maintenance.

Factors affecting wear and maintenance frequency

The operating environment and fluid characteristics greatly influence the wear of a pressure relief valve and, consequently, the frequency with which pressure relief valve maintenance should be performed. In particular, the following factors have an impact:

- Operating pressure: systems that constantly operate at high pressure subject valves to greater stress, accelerating wear and tear and requiring more frequent maintenance;

- Type of fluid: corrosive, abrasive fluids or fluids containing suspended particles (such as unfiltered water, aggressive chemicals, or sludge) can quickly damage the internal surfaces and seals of the valve;

- Activation frequency: A pressure relief valve that activates frequently to release pressure is subject to greater wear than one that remains closed for long periods. The opening and closing cycles put stress on the internal mechanisms and seals.

- Temperature: Extreme temperatures, both high and very low, can affect the integrity of the materials of the seals and metal components, reducing their flexibility and wear resistance.

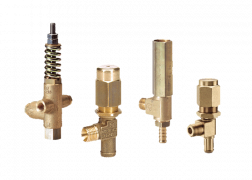

Hawk Pumps solutions for high-pressure relief valves

The maintenance of pressure relief valves is very important for Hawk Pumps, which is why it designs and manufactures accessories that not only guarantee excellent performance but are also built to facilitate maintenance and ensure long life.

The wide range of high-pressure relief valves available in the catalog is designed to ensure reliability and superior performance in a variety of industrial applications: whether for washing systems, industrial pressure washers, or fluid management systems, the valves offered are built to last and deliver maximum operational efficiency.

Choosing Hawk Pumps high-pressure relief valves means opting for products made from top-quality materials that are resistant to corrosion and wear, guaranteeing long life and a significant reduction in maintenance costs, as the need for replacements and repairs is drastically reduced. Each valve is the result of precision engineering, specifically designed to offer unbeatable protection against overpressure while maintaining the overall efficiency of the system.

To learn more, find the solution that best suits your needs, or request technical support on maintenance procedures, please contact us: our team of experts is at your complete disposal to provide you with personalized advice.

Share this Article