Pump cavitation: what it is and how to avoid it

A comprehensive guide to understanding and countering this damaging phenomenon for industrial pumps

In the world of industrial pumps, a frequently recurring term that instills fear in operators is “cavitation.” This seemingly invisible phenomenon can cause significant damage and drastically reduce the life and efficiency of a pump. Consequently, understanding what cavitation is, what causes it and, most importantly, how to prevent or mitigate it is critical to ensuring reliable and prolonged operation of pumping systems.

Specifically, cavitation consists of a physical process that occurs within a moving liquid when the local pressure drops below the vapor pressure of the liquid itself at operating temperature. In simpler terms, vapor bubbles are formed within the liquid that violently implode as they move to higher pressure areas. These implosions generate extremely intense localized pressure waves capable of eroding all affected surfaces, regardless of the construction material.

The main causes of cavitation

Several factors can contribute to the occurrence of cavitation in a pump, and identifying the root cause is the first step in implementing the most effective prevention strategies. Predisposing factors include:

- insufficient suction (NPSHa too low): the available Net Positive Suction Head (NPSHa) is the absolute liquid pressure at the pump inlet, net of vapor pressure. If the NPSHa is too low compared to the Net Positive Suction Head required (NPSHr) by the pump, the liquid pressure inside may fall below the vapor pressure, triggering bubble formation. This is often caused by excessive suction height, high pressure drop in the suction line (due to too long or insufficient diameter pipes, tight bends, partially clogged filters or valves), or too low pressure in the suction tank;

- liquid temperature too high: as the temperature increases, the vapor pressure of the liquid increases. If the vapor pressure gets too close to the suction pressure, the risk of cavitation increases significantly;

- excessive pump rotation speed: too high a rotation speed can cause the pressure to drop rapidly, promoting the formation of vapor bubbles;

- partial obstructions at the pump inlet: partial restrictions or obstructions in the suction line or pump inlet can increase the speed of the liquid and decrease its pressure, creating cavitation risk zones;

- inadequate pump design for operating conditions: a pump that is not properly sized for the specific needs of the system (flow rate, head, type of liquid) may be more susceptible to cavitation.

The harmful effects of cavitation

Violent implosions of vapor bubbles caused by cavitation can have devastating consequences for the pump. Here are some examples:

- erosion of metal surfaces: pressure waves generated by implosions gradually erode the material of internal components, creating cavities and roughness. This leads to reduced pump performance and, over time, the need for costly repairs or replacement;

- excessive vibration and noise: cavitation is often accompanied by noise similar to that produced by gravel flowing inside the pump and abnormal vibrations, which can damage bearings and other mechanical components;

- reduction in pump efficiency: erosion of internal components and turbulence caused by the presence of vapor bubbles reduce the pump's ability to transfer energy to the liquid, decreasing its efficiency and increasing energy consumption;

- premature failure: if not addressed, cavitation can lead to premature pump failure, resulting in operational interruptions and high maintenance costs.

How to avoid cavitation?

Preventing cavitation is always preferable to repairing the damage it may cause. Here are some key strategies:

- reduce the temperature of the liquid, since keeping the temperature of the pumped liquid below critical limits can significantly reduce the risk of cavitation;

- reduce the rotation speed of the pump, if possible, because it can help prevent pressure drop;

- avoid obstructions at the pump inlet by making sure that the pump inlet is free of obstructions and that the liquid flow is uniform;

- choose the right pump for the application, with an NPSHr appropriate for the suction conditions of the system, which is critical in the design phase;

- install a pressure indicator at the intake so that it can provide an early indication of potential intake problems. The pressure detected by the indicator should always be positive. We at Hawk recommend 0.5 to 3 bar.

- use the double suction port: this type of configuration allows the liquid flow to be divided between two symmetrical inlets, reducing the suction speed at each point and lowering the risk of pressure drops below the vapor value. It also improves hydraulic load distribution on the impeller, contributing to more stable and quieter pump operation. It is a particularly effective solution in applications with high flow rates or critical suction conditions.

Hawk solutions to prevent cavitation

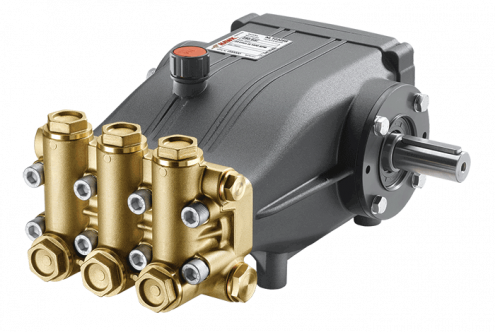

Hawk Pumps places great emphasis on designing and manufacturing high-pressure pumps that minimize the risk of cavitation. They are all designed with optimized internal geometries to ensure uniform liquid flow and reduce internal pressure drops.

To ensure reliable and long-lasting operation, Hawk recommends strictly following the installation and maintenance instructions provided, paying particular attention to the characteristics of the suction line. Choosing high-quality accessories, such as appropriate diameter piping and low-loss fittings, helps maximize the available NPSHa.

Relying on Hawk pumps means choosing products designed to deliver high performance and long service life, minimizing cavitation problems if the system is properly designed and operated. Contact us now for information!

Share this Article