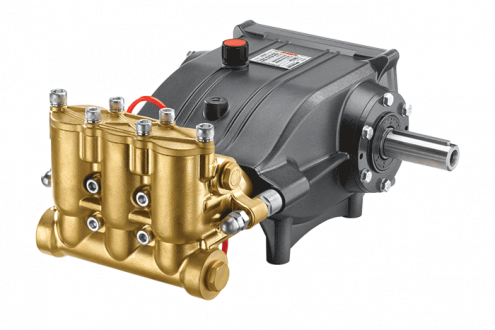

Ceramic piston pumps: advantages and reliability

An in-depth analysis of how ceramic pistons revolutionize the reliability, efficiency, and durability of high-pressure pumps

At the heart of every piston pump, the material used to construct the pistons themselves is a determining factor in the reliability, performance, and longevity of the entire system. For decades, the industry has relied on metal pistons, but technological advances have led to the adoption of a significantly superior material for the most demanding applications: ceramics.

Ceramic, in its most technical sense, represents a qualitative leap forward for components subjected to stress. Its composition and manufacturing process make it a material with unique properties, ideal for tackling the most difficult challenges in the context of high-pressure pumps.

In this article, we at Hawk will provide an overview of this component and its main advantages over its metal counterpart.

The heart of the pump: the role of pistons

Before analyzing the advantages, it is useful to remember that in a volumetric piston pump, these components are directly responsible for the movement of the fluid. With an alternating motion (back and forth) inside a cylinder, they create the pressure difference necessary to suck in the fluid at the inlet and push it out at high pressure.

This repetitive, high-frequency movement puts the pistons under constant mechanical stress, as well as in constant contact with the seals and the fluid, subjecting them to continuous friction and possible chemical or abrasive attack from the pumped liquid. In a high-pressure application, where piston speeds are high and the forces involved are considerable, wear on these components is an inevitable phenomenon which, if not managed, quickly compromises pump efficiency, reduces pressure, and causes leaks.

For this reason, choosing the right piston material is the first step in ensuring long-term performance.

Traditional pistons: the limitations of metals

Historically, pump pistons have always been made of metal, often stainless steel or other hardened metals. Although these materials offer good structural strength, they have significant limitations, especially in demanding applications:

- Wear and friction: metals, however hardened, are subject to abrasive wear, particularly when handling fluids containing suspended particles. Continuous friction against the seals and high-speed movement cause surface degradation which, over time, reduces efficiency and creates grooves that compromise the seal.

- Corrosion: stainless steel is resistant to many chemicals, but not all. The use of aggressive fluids (such as acids or saline solutions) can trigger corrosive processes that damage the surface of the pistons, leading to leaks and failures.

- Need for constant lubrication: friction between metal pistons and seals is high, making an effective and constant lubrication system essential. If lubrication is insufficient, heat and friction can cause accelerated wear, leading to sudden failure;

- Limited lifespan: due to these factors, metal pistons have a shorter operating life and require more frequent maintenance (replacement of seals and, eventually, the pistons themselves) to maintain performance.

These limitations are particularly evident in high-pressure applications, where stresses are amplified and the cost of machine downtime can be high.

The advantages of ceramic pistons

The adoption of ceramic as a material for pump pistons has solved most of the problems associated with metals, introducing a series of indisputable advantages that justify its choice, especially in professional and industrial contexts:

- Exceptional wear resistance: ceramics, particularly alumina or zirconia oxide ceramics, are among the hardest materials in existence, with a surface hardness that far exceeds that of steel. This makes them extremely resistant to abrasive wear. Friction with seals is minimal and the surface retains its integrity for a significantly longer period of time.

- Complete corrosion resistance: ceramic is an inert material, so it does not react with most chemicals, acids, alkalis, or saline solutions. This advantage makes it the ideal choice for applications where the pump must handle aggressive liquids, such as in the chemical, food, or pharmaceutical industries, ensuring component integrity and preventing fluid contamination.

- Smooth, low-friction surface: the surface of the ceramic pistons is extremely smooth and mirror-polished. This flawless finish drastically reduces friction with the seals, lowering the operating temperature. Reduced friction also means minimal wear on the seals, which translates into longer life cycles and less maintenance.

- Lower maintenance requirements: thanks to their resistance to wear and corrosion, ceramic pistons guarantee a significantly longer service life. The seals, working on a flawless, low-friction surface, last longer, which drastically reduces the frequency of maintenance and machine downtime, cutting long-term operating costs.

Ceramic pistons for pumps: ideal applications

Ceramic pistons for pumps have established themselves as the preferred solution in all applications requiring high reliability, durability, and compatibility with different fluids. The main sectors in which the use of this material has become standard include:

- High-pressure washers and washing systems

- Food industry

- Chemical and pharmaceutical industry

- Petrochemical sector

The robustness and reliability of ceramic pistons therefore represent a long-term investment, resulting in savings on maintenance costs and increased productivity.

Choose Hawk pumps with ceramic pistons

Thanks to its in-depth knowledge of the sector's needs, Hawk Pumps has made quality and reliability a priority. For this reason, our piston pumps are designed using ceramic pistons. This choice is not accidental, but the result of a constant commitment to excellence, aimed at offering our customers the most durable and efficient solutions on the market.

To find out more about the complete range of ceramic piston pumps, contact us: our team of experts is at your complete disposal to provide advice and technical support and help you choose the ideal pump for your specific needs.

Share this Article